INDIRECT FIRED/RADIATION OVENS

Heat Transfer

Heat is created in the combustion chamber and then transferred to the rest of the oven via radiant heating tubes. The main circulation fan ensures efficient heat transfer via the tubes. Each zone is fitted with turbulence fans that enhance the movement of the radiant heat through the chambers. Extraction fans return the excess heat back to the combustion chamber for re-circulation.

The product is baked in the ambient air within the oven which is heated through the radiant heat given off from the heating tubes.

Top and Bottom Heat can be controlled with dampers. Each Section is fitted with dampers.

Baking Times and Temperature

Baking Times are variable from 10 to 50 minutes, but any other timing requirements can be arranged to meet the customers’ requirements.

Baking Temperatures range from 100 °C to 300 °C.

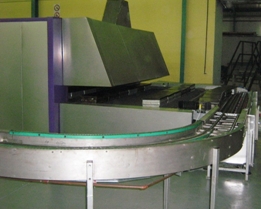

Conveyor

A wire mesh belt or a solid band belt transports the products through the oven. Tracking of the belt can be automatic and all our ovens are fitted with pneumatic belt tensioners.

All our wire mesh belts are imported from the USA.

Steam

The steam section is fitted at the beginning of the oven. There is no circulation in this area. Steam will have to be supplied from a boiler. All the necessary pipes and fittings are built into the steam section.

Available in electric, gas or fuel (oil).

Ovens widths can be manufactured from 800mm(.8m) wide to 3500mm(3.5m), and from 5000mm(5m) in length up to 60000mm(60m) long, depending on the bakers needs and requirements.

BISCUIT OVENS

The design and heating system of the biscuit oven is very similar to that of the indirect fired ovens, although no turbulence is provided for and baking is done in static heat. Extraction fans can be fitted to remove moisture where required.

Biscuit ovens are usually between 800mm and 1200mm. This is to accommodate Moulders and Cutters which are fitted onto to the oven.